Top-Notch Quality: Part 2

How do you plan for a winning season? The Bison men’s basketball team could probably answer that question: high expectations, confidence, discipline, and years of practice. And they should know…they worked incredibly hard to earn a spot in the NCAA tournament, and made program history with an upset victory in round 2. A win in the NCAA Tournament was a huge accomplishment for the Bison.

Since you parked the combine last fall, we know you’ve been planning for your next winning season. Keep in mind that hybrid and variety selection are the first steps you can take to succeed in 2014. Seed quality is at the center of this decision.

Each day at Peterson Farms Seed, we strive for seed quality excellence. We follow strict protocols to ensure that our growers are getting the best seed, and it shows in the bag.

In our desire for higher quality, we simply treat the soybeans more gently during handling and processing…

We hire a trucking firm that specializes in the gentle transport of seed to bring farm-binned production soybeans into our Prosper plant. Their meticulous efforts help to maintain varietal purity. And their consistent use of grain vacs reduces the mechanical damage that frequently occurs when using augers.

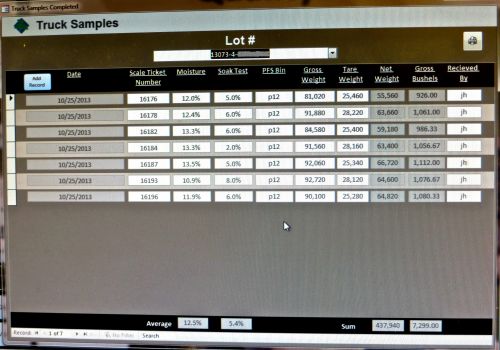

When the trucks arrive at PFS, each truck load is sampled, with samples undergoing moisture and soak tests. Click here for more information on how we test our samples.

As the trucks are unloaded, they are moved into bins that have let down ladders. This ladder, inside each bin, slows the flow of the beans as they move back and forth down each padded step. The goal is to minimize damage to the beans.

Once the conditioning process begins, hourly samples are collected from the cleaners. Gram weights, moisture, seed counts, soak test, and grain temperature are recorded for each lot.

Gram weights and soak numbers are monitored closely for both good cut and low cut, pictured below, to ensure the gravity tables are operating correctly, or to indicate that the tables need adjusting.

The goal is to see a significant difference in soak numbers between the good cut and the low cut. This indicates that the damaged kernels and the good kernels are being separated. We want to achieve soak numbers below 10 on the good cut.

We also monitor grain temperature very closely. Our plant shuts down when we hit our cold temperature target as handling the product in extreme cold can create stress on the bean and reduce germination.

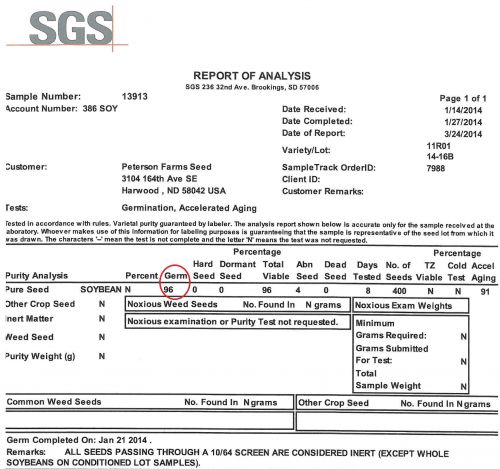

A portion of the collected hourly samples are added to the lot sample bag, which gives us a representative sample of the entire lot. At the completion of the lot, samples are sent to two labs for final germ testing. The photo below shows a final germ report of 96%.

Achieving excellence requires several attributes: discipline, continual learning, practice, and planning. At PFS, we apply all of these attributes within our strict quality protocols.

So what does this mean for the growers in our region? Our special trucking arrangements combined with gentle handling techniques once the seed is here gives us the very best product to work with. Once our processing begins, our frequent monitoring and testing techniques allow our staff to adjust the processing equipment to get the best finished product out of each lot.

You can count on Peterson Farms Seed to continue to run our soybean seed through the most rigorous testing standards in the industry. The result? A winning season for you.