The Corn Whisperer: Did Mike Achieve 400 Bushel Corn?

It was on a tour of the Monsanto Water Utilization Learning Center in Nebraska that Mike Larson, Peterson Farms Seed Sales Manager and corn guru, was struck with an idea: Is 400-bushel corn attainable? The idea was born while surrounded by researchers who were as passionate about corn as he was!

He admits that, from the beginning, the project sounded a bit out there. After visiting with others, including John McGillicuddy who gave him some good ideas and was interested in the project and its potential as well, Mike decided to go all in and give this ambitious project a try.

The methods and tools are unique: a planter grid made out of a sheet of plywood, an irrigation system built from PVC pipes and a 30-gallon poly drum, harvesting and shelling the corn by hand, and willing labor in the form of summer and fall interns. But, with the uniqueness comes imagination and a drive to achieve something that sounds… well, out there!

Since 2013, Mike’s project has been built around exploring the genetic potential of a handful of Peterson Farms Seed hybrids. 2016 was the 4th year he attempted to break 400 bu/A mark.

To start, the field surrounding the ‘Feeding the 400’ plot was fertilized for 200 bu/A corn and planted at a population of 34,000 plants per acre.

“While in Nebraska, I hit it off with one of the team members that had a shared interest in corn. He pulled out a book on corn production from around 1930 and in this book he pointed out a page showing different pictures of equidistant spacing techniques. One was laid out with squares and the other was diamond shaped, which was the birth of the planter made out of a sheet of plywood,” explains Mike.

On May 1, using the “High Tech Caveman 2.1 Equi-distance Planter”, the plot was planted in a diamond-shaped pattern with each plant getting 1 square foot to call home. This equates to a final stand of 43,560 plants/A.

“In the past, we used a square-shaped pattern but quickly realized that we could better utilize the space using a diamond-shaped pattern,” said Larson. “The changes that come from comparing year-to-year results show the importance of being flexible and open-minded in your approach to yield.”

Next, 300 units of ammonium sulfate were spread on June 10th. During the week of July 4th, two Peterson Farms Seed summer interns “spoon fed” the plot (via PVC pipe and a 30-gallon poly drum) with 40 units of Nitrogen and 40 units of Potash in a liquid slurry that added what would equal a ½ inch of H2O (otherwise known as rain). The spoon feedings were continued every Monday until August 15th.

Up until this year, this would have ended the spoon feeding schedule, but… Enter the first ever fall intern, Ruth, who continued the same protocol for three additional weeks.

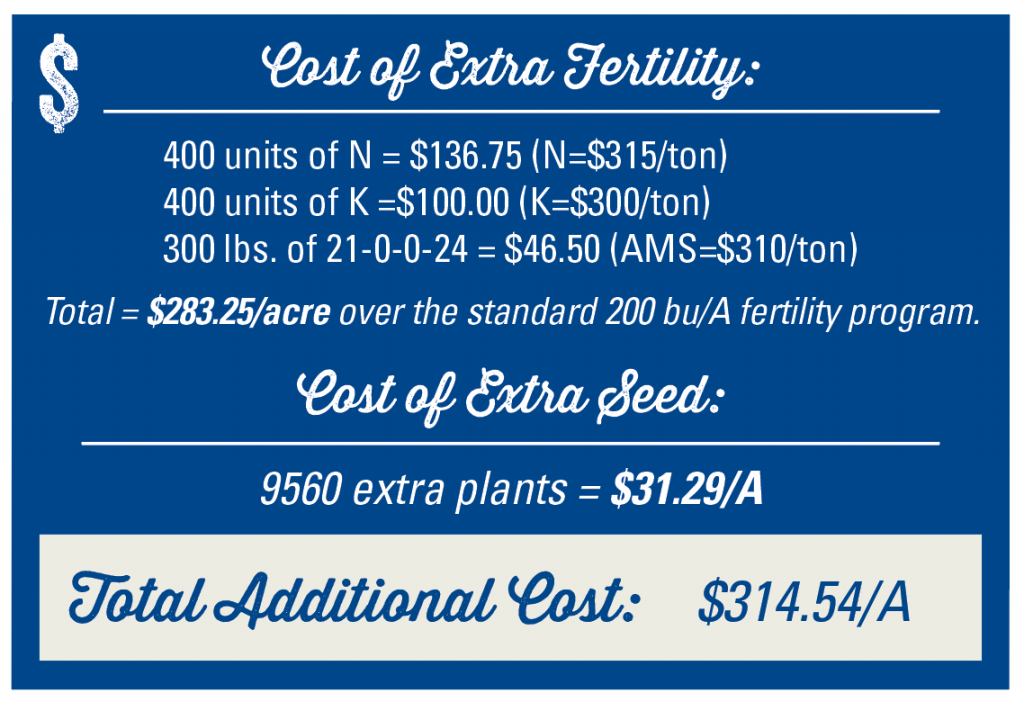

Of course, during this process, it’s worth noting the extra costs that are associated with these ‘unique methods’. See below for a breakdown of the additional costs incurred over the growing season (This example does not cover any of the application cost or labor).

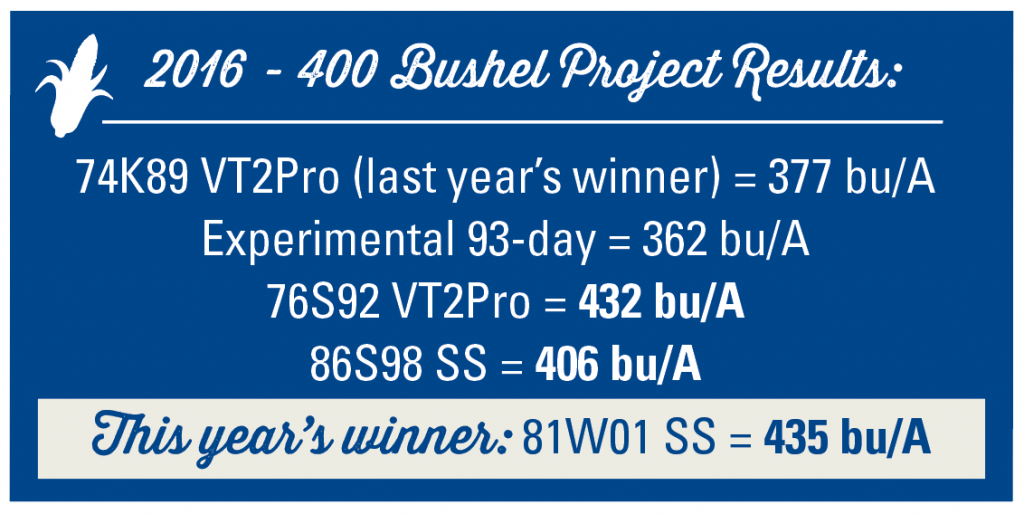

After all of the time, care, and attention, it was the moment of truth. The rows were hand-harvested and hand-shelled (yes, it is a LOT of work) and the year-end results were tallied and factored down to 14.5 moisture:

Yes, Mike and his team finally achieved their goal with three out of five tested hybrids surpassing the 400-bushel mark!

When taking the additional yield over the 200 bu/A field average multiplied by a current cash price of $3/bu and subtracting the additional out-of-pocket cost of the seed and fertilizer, the additional income of the winning hybrid, 81W01SS, was calculated at $390.46/acre.

The question is: Why did Mike break the 400-bushel barrier on 3 out of 5 hybrids? Did the additional three weeks of feeding make the difference? It certainly did not hurt, but Mike thinks the ideal summer temperatures and nearly perfect growing season in the region helped make for some above-average kernel weights which translated into higher yields.

What’s next for Larson? “Well, 500 of course!” was his quick, laugh-filled answer.

As always, Mike loves talking about anything involving corn, including his 400 (now 500?) bushel project so give him a call anytime!